NanoFlowSizer: the technology behind this new particle sizing instrument

Conventional DLS

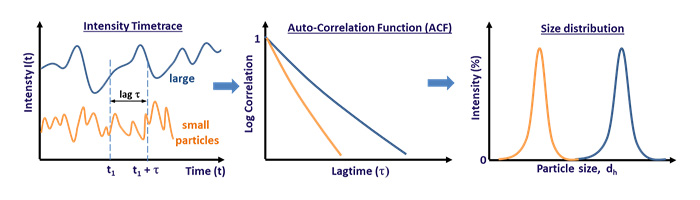

Dynamic light scattering (DLS) is a well-accepted technology for measuring particle size and size distribution of nanoparticles in liquids. It is based on the measurement of fluctuations in light scattering caused by Brownian motion of suspended particles.

For Brownian diffusion, the frequency of scattered intensity fluctuations depends on the particle size; smaller particles diffuse more rapidly and thus produce higher frequencies. Therefore, the temporal fluctuations in light scattering hold information on the particle size.

Limitations conventional DLS

Standard DLS measurements need to be performed under static conditions ensuring that particle movement is solely caused by Brownian motion and not influenced by other factors like liquid flow.

Additionally, conventional DLS cannot be applied to relative turbid suspension without dilution, while these are often encountered in industrial or process environments. Since nanosuspensions are in motion during processing and vary in turbidity levels conventional DLS is not very suitable for process analytics applications.

How do results from different dynamic light scattering instruments compare?

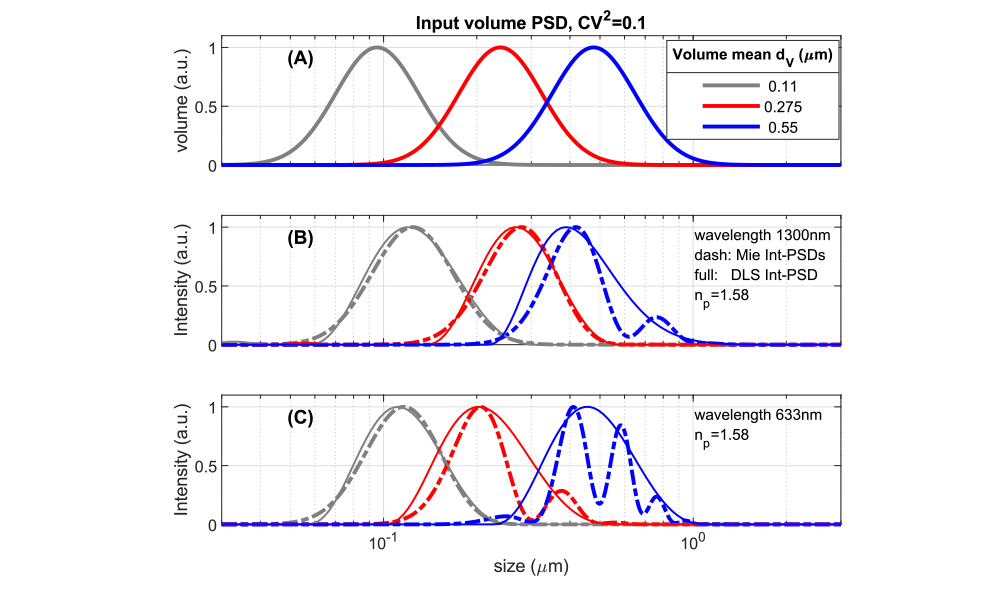

Explanation of how results from DLS instruments at different wavelengths and scattering angles are related using practical examples, computer simulations and established light scattering theory, in the context of recently introduced novel Spatially Resolved DLS technology using Near InfraRed light.

EMA/FDA: “one of the greatest challenges in bringing new nanomedicines to market is accurately determining their particle size during manufacturing”

Spatially Resolved Dynamic Light Scattering

To overcome the limitations of conventional DLS for process analytical applications InProcess-LSP developed a new innovative technology: Spatially Resolved Dynamic Light Scattering (SRDLS). SR-DLS allows particle size characterization in process flows and can measure highly turbid suspensions without dilution.

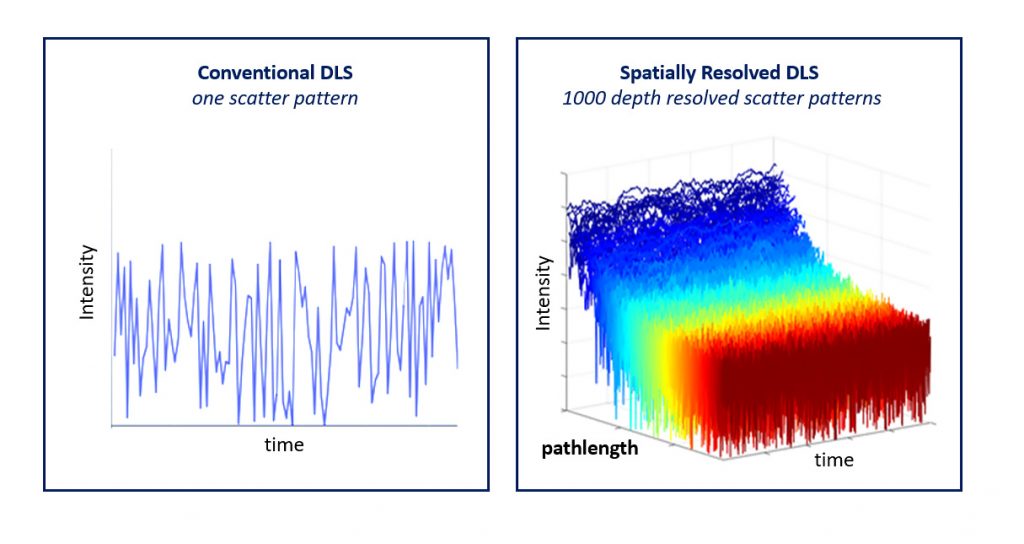

Low coherence interferometry

The NanoFlowSizer technology is based on low coherence interferometry providing light scattering information as a function of optical pathlength (pathlength or depth in the sample).

The depth-resolved light scattering holds information on particle movement caused by both Brownian motion as well as flow rate. The contribution due to Brownian motion is used for the calculation of the particle size characteristics, while the flow rate information is obtained instantaneously for every measurement as well.

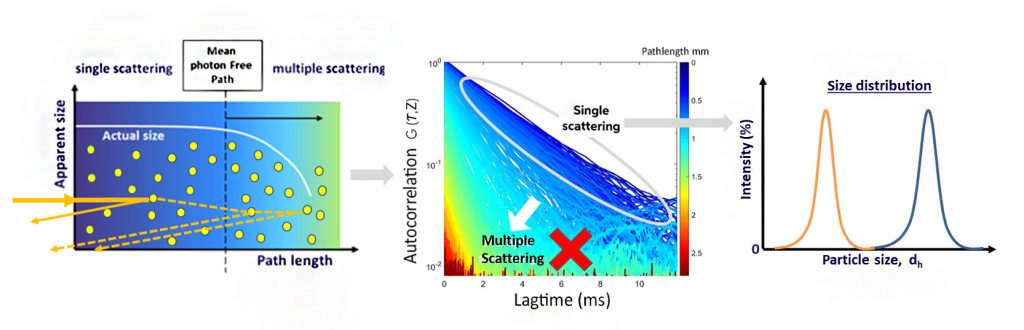

Nanoparticle analysis of highly concentrated and optically turbid samples

The spatially resolved data in combination with smart algorithms allows the NanoFlowSizer to distinguish single from multiple scattered light, which is fully automated within the XsperGo software. As a result, obtained data of highly turbid samples is automatically corrected for multiple scattered light (since multiple scattered light will not be used for adequate particle size analysis in DLS).

Figure: Left: the chance that unwanted multiple scattering occurs increases with the turbidity level of the sample and the pathlength of the light. When multiple scattering occurs, the applied algorithms of the NanoFlowSizer will detect automatically at which depth (pathlength) this occurs. Middle: the obtained auto-correlation functions originated form single scattered light are automatically selected, for processing of particle size information, while those related to multiple scattering are automatically discarded. Right: Particle size information is obtained by processed single scattered light data only.

The measurement and processing of the data into particle size information, such as z-average, PSD (particle size distribution) and PDI (poly dispersity index), takes place within 10s.

We are extremely impressed by the system and the quality of the data!

Top 5 vaccine manufacturer

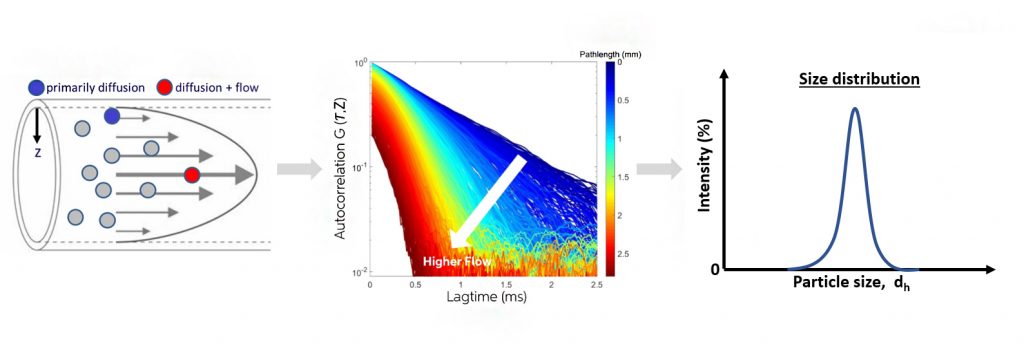

Nanoparticle characterization under flow

Conventional DLS requires the sample to be at rest. As spatially resolved data are available, the NanoFlowSizer is capable of fitting and distinguishing particle movements caused by flow and Brownian motion. The XsperGo software is able to correct for flow effects on measurements using the relevant Brownian motion information.

These clear advantages make the NanoFlowSizer the ideal solution for inline or online measurements, providing continuous real-time process feedback on nanoparticle size characteristics, a powerful Process Analytical Tool.

Configurations

Fast analysis:

- Offline (R&D)

- Offline (QC)

- Inline

- Online

- At-line