The ONLY TRUE inline Nanoparticle Analyzer in the Market today

The need for inline nanoparticle sizing

The use of nanoparticles has become increasingly popular in multiple industries, such as pharma, chemicals, cosmetics, and food & dairy.

Nanotechnology in healthcare has an exceptional potential to address a diversity of therapeutic issues by providing better diagnostics and therapy. A broad range of nanoparticle enabled products are available for pharmaceutical medical applications (drug delivery), including liposomes, polymeric nanoparticles and lipid-based nanoparticles.

Unique benefits of SR-DLS

- Analysis of highly turbid suspensions

- Measurement in flow

- Sample preparation not necessary

- Real-time process control

- Monitoring of continuous manufacturing possible

Learn more about SR-DLS

Limitations of conventional technologies…

- Low control during the production process

- Interruption of the manufacturing process flow at quality control stage

- Need for off-line laboratory analysis, could result in potential delays

- Impossible to carry out realtime control of nanoparticle size during continuous manufacturing

- Batch to batch quality might vary

- Delayed process quality feedback, due to long analysis time

A unique nanoparticle sizer: the NanoFlowSizer

The importance of particle size analysis

Particle size and Particle size distribution of nanoparticles could directly affect efficacy and safety for patients in pharma applications.

Since the behavior of particles at nanoscale depends highly on these properties, control of nanoparticle size is paramount from development up to manufacturing.

Uncompromised monitoring

Pharma industry demands complete control over manufacturing processes that need to comply with stringent regulations and demands. As a result sophisticated, highly efficient Process Analytic Technologies (PAT) might be required.

However, there is currently a lack of suitable PAT solutions for monitoring nanoparticle size and particle size distribution.

Nanoparticles and their applications

Nanoparticles could be natural or synthetic particles by nature with a size 1-1,000 nm. Due to their ultra-small size they have a large surface area in relation to their volume, providing them with special properties.

Nanoparticles are present in many of the items in our everyday life, such as sunscreens, medicines, inks etc.. Of special interest within the pharmaceutical industry, nanoparticles could be used in different formulations, such as drug delivery systems for transporting systems through the body.

The InProcess-LSP solution

The NanoFlowSizer

- Reduction in analysis time, results in seconds

- Increased process understanding

- Particle size information in real time

- Reduction of production time

- Potential for significant batch reductions

Why is the NanoFlowSizer different?

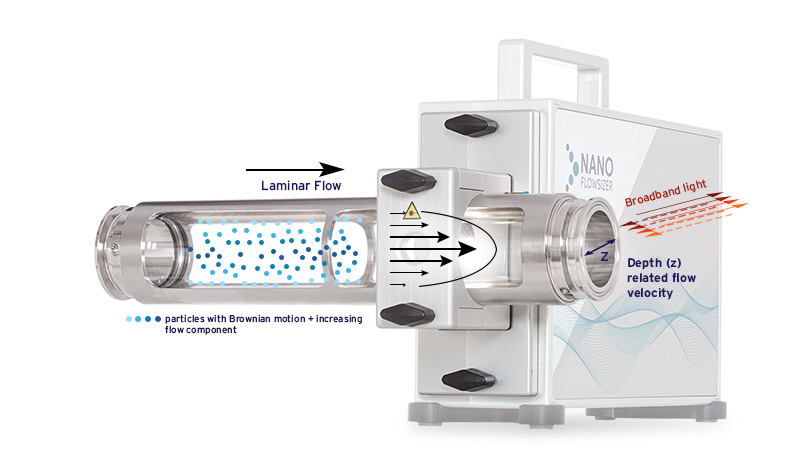

The NanoFlowSizer (NFS) is a new non-invasive nanoparticle size analyzer developed by InProcess-LSP. This technology is the only one capable of analyzing particle size and size distribution measurements for liquid materials. This can be done inline at production flow with no need to dilute or treat sample material.

Results every 10 sec

With the NanoFlowSizer, nanoparticle size measurement takes place in less than 10s, enabling continuous real-time monitoring.

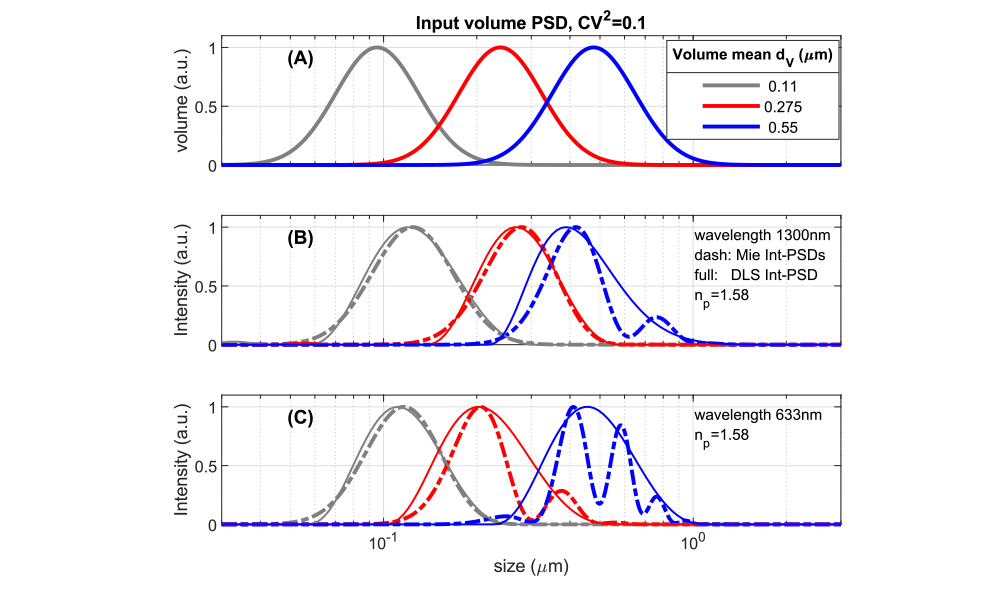

How do I compare different DLS instruments?

Dynamic Light Scattering is used to measure the hydrodynamic size and size dispersity of nanoparticles in suspension. The configuration of a DLS instrument can affect the measured particle size.

We explain how results from DLS instruments operating at different wavelengths and scattering angles are related using practical examples and light scattering theory.

We are extremely impressed by the system and the quality of the data!

Top 5 vaccine manufacturer

Process monitoring

Poor process control could result in uncertain product quality, leading to high rejection rates in batch production for (pharmaceutical) products.

The inline functionality of the NanoFlowSizer allows complete control over the production process. This could be an advantage for high-quality demands in pharmaceutical manufacturing.

Save unnecessary costs

Having full control over the quality of your product during manufacturing could lead to a reduction of batch rejection related to nanoparticle size. This reduces the need for offline laboratory analysis, preventing delays during manufacturing. As a result, the NanoFlowSizer can provide major annual savings.

“As an inline instrument, the NanoFlowSizer is a powerful non-invasive Process Analytical Tool allowing close monitoring of particle size characteristics in your process.”

Average particle size and size distributions in seconds

- Continuous size characterization of nanoparticles during processing

- Inline Process Analytical Tool

- Non-invasive measurement

- Real-time process feedback

- Measurement of highly turbid materials

- High-speed measurement

- Inline, online and offline operation

- For very small (<<mL) to large sample volumes

Up to millions is lost per year due to the absence of appropriate

particle size monitoring solutions…

What can the NanoFlowSizer mean for your process?

Excellent quality control

Measuring particle size and distribution in real time allows process engineers to correct processing conditions.

Outcome: No discard of batches after production..

Measuring particle size and distribution in real time allows process engineers to correct processing conditions.

Outcome: No discard of batches after production..

Timely Analysis

The NanoFlowSizer offers significantly faster analysis time and no sample preparation time.

Particle size data is measured in less than 10 sec.

Outcome: significant reduction of total analysis time.

The NanoFlowSizer offers significantly faster analysis time and no sample preparation time.

Particle size data is measured in less than 10 sec.

Outcome: significant reduction of total analysis time.

Non-contact Measurement

The device measures non-invasively concentrated turbid solutions eliminating the need to extract & dilute samples. This allows sterile manufacturing.

Outcome: Safe products.

The device measures non-invasively concentrated turbid solutions eliminating the need to extract & dilute samples. This allows sterile manufacturing.

Outcome: Safe products.

Real-time measurement

Greater process insight and control in real time promotes efficiency as process engineers have a better understanding and control over manufacturing dynamics.

Outcome: Faster infirmation about product quality.

Greater process insight and control in real time promotes efficiency as process engineers have a better understanding and control over manufacturing dynamics.

Outcome: Faster infirmation about product quality.