NanoFlowSizer system and modularity

Flexibility in system configuration is key

The flexibility of measurement configurations is a key attention point for InProcess-LSP.

Various applications and processes from R&D up to commercial production environments come with different objectives, requirements and configuration possibilities.

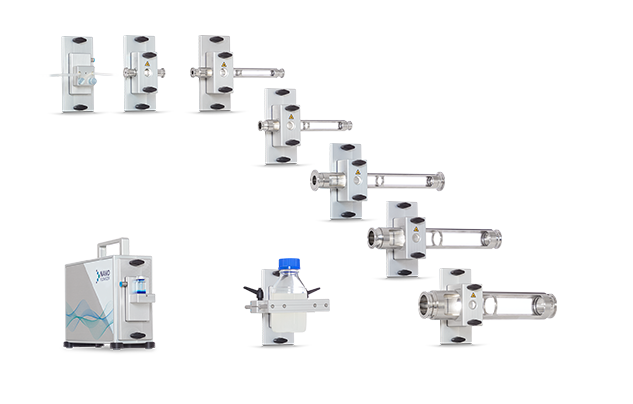

Replaceable modules

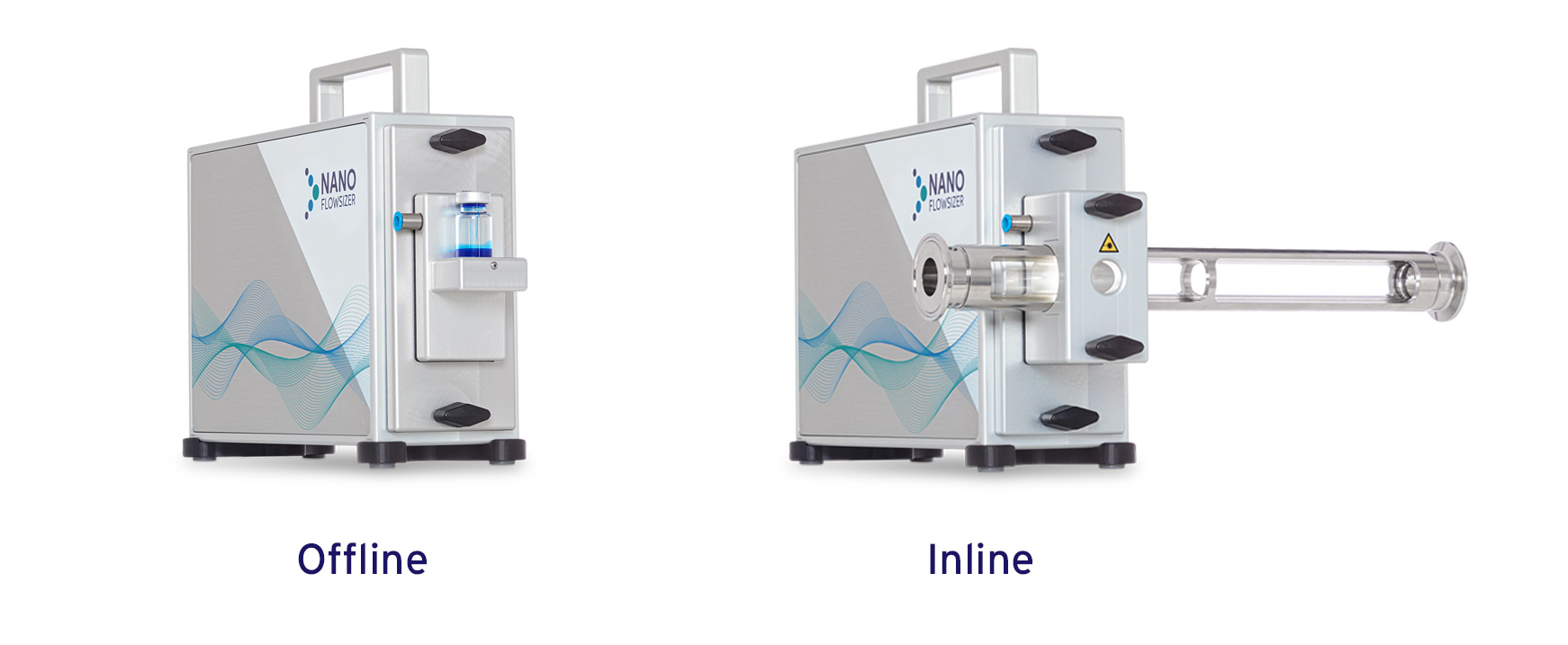

The NanoFlowSizer allows particle size measurements for small to large scales based on inline, online or offline analysis.

Various replaceable sample modules are available to equip the NanoFlowSizer with an optimal interface to your sample or process.

Pharma Grade flow cells

- Flow-cells are Pharma grade and suitable for SIP/CIP

- Temperature & Module recognition sensor integrated

- Connection for external PT100 temperature sensor possible

- Air-drying functionality to prevent condensation

Full flexibility

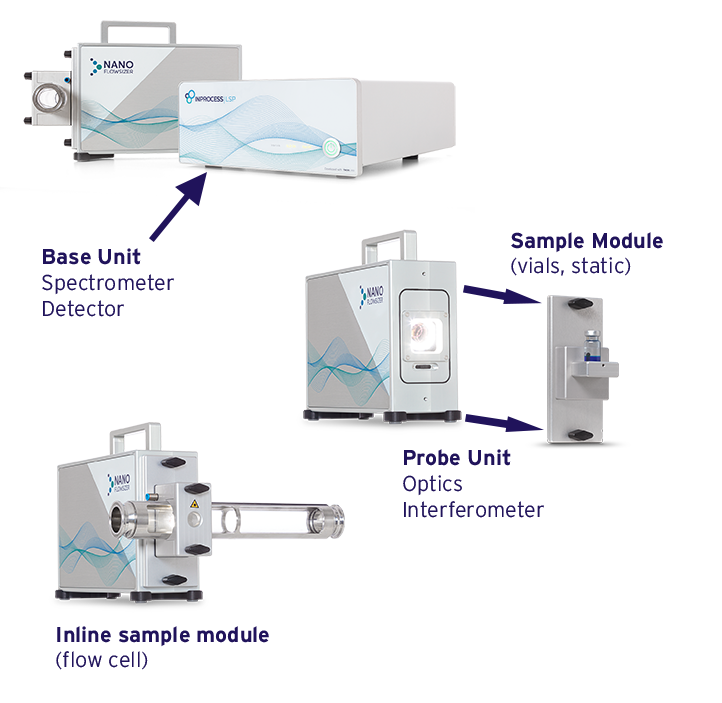

The NanoFlowSizer elements

The NanoFlowSizer consists of three main elements :

- Probe Unit: Interferometer + Optical components

- The Base Unit: Spectrometer and light source

- XsperGo software: instrument operation and data processing

The NanoFlowSizer is a flexible modular system offering different functionalities depending on the module used.

Low coherence interferometry

Low-coherence-Near-Infrared light from the source in the Base Unit is transmitted through an optical fibre to the Probe Unit, where it illuminates the container/flow cell containing the nanosuspension. The light is back-scattered by the nanoparticles. The back-scattered light is then mixed with the source light in the interferometer. This interferometric signal is transmitted back to the spectrometer in the Base Unit through the same fiber.

Subsequent Fourier analysis of the ‘interferograms’ (across the different wavelengths) provides the depth-resolved scattering data, at a rate up to ~100kHz. The fluctuating scattering signals at all depths are then processed, via autocorrelation analyses and patented spatial filtering and flow-correction algorithms, into real-time particle size information using the XsperGo software package. Supplemented with real-time quality indicators, detailed information is thus obtained on nanoparticle size and size distribution to control the quality of products and processes.

Inline and online configurations

The NanoFlowSizer as a true PAT tool is specifically designed for effective inline and online analysis, interfacing dedicated flow cell sample modules with your process.

These flow-through cells can be mounted easily using well-accepted industry-standard Tri-Clamp connections into your process line.

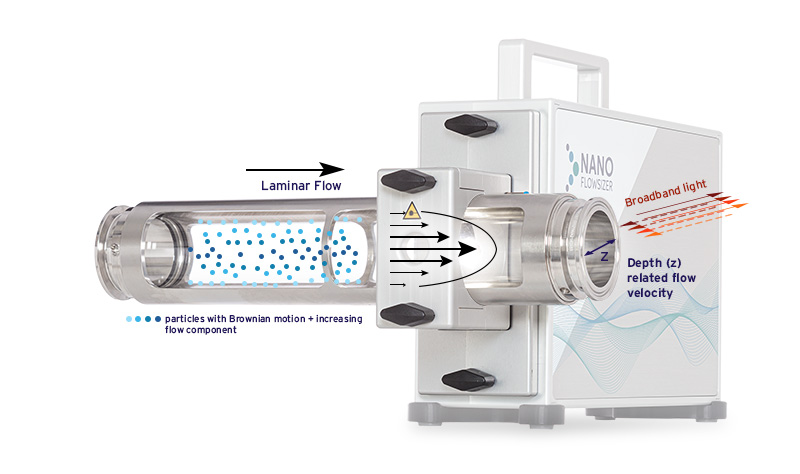

Laminar flow

When the nature of the suspension flow becomes turbulent (non-laminar) or non-stable, the quality of the measurements may be compromised. Therefore, high quality stable pumping systems are recommended along with the appropriate flow cell. Since flow speed is also directly measured by the instrument, real-time diagnostics indicate the data quality for each measurement point.

Image left:

Development of a laminar flow for adequate in/online measurements

Inline configuration

NanoFlowSizer at manufacturing plant

Inline NanoFlowSizer configuration (2.0 inch Flow Cell Sample Module) in manufacturing

Real-time, continuous particle size measurements of a Titanium Oxide Synthesis at various conditions by Micro-Flow Cell Sample Module Configuration.

The NanoFlowSizer is a flexible modular system allowing inline and offline analysis

Offline configurations

Besides the unique capabilities of the NanoFlowSizer to measure in flow, measurements of static samples by offline analysis are possible as well. The vial sample module for static measurements is a helpful tool for non-invasive and fast analysis of (closed) glass vials (without dilution). This sample modules is also used for performance verification with particle size reference standards.

Dynamic studies, such as monitoring particle growth in a static sample can be easily performed, either in a vial, cuvette or larger beaker of flask. For beakers and flasks, the flask sample module is a flexible tool that can handle glass bottles typically up to 1L. For direct analysis of end-product in glass flasks the flask sample module allows direct measurement through the glass bottle without any dilution or sample handling.

NanoFlowSizer configurations overview

Configurations

Customized sampling modules

In case currently available sample modules are not suitable for optimal measurement of your product or process, InProcess-LSP offers the possibility to create optimal and specific designs for customers if required. In principle particle size information of nanosuspensions can be obtained by the NanoFlowSizer as long as the measurement takes place through a glass interface. Please do not hesitate to contact us for more information.

Fast and real-time process control

Configurations

Fast analysis:

- Offline (R&D)

- Offline (QC)

- In-line

- On-line

- At-line