Roadmap to your process control

InProcess-LSP recognizes the importance of delivering not only innovative instrumentation but assure adequate performance and optimal alignment with customer objectives. Therefore, a step-wise implementation approach is recommended between initial feasibility screening and final implementation of the technology for new applications.

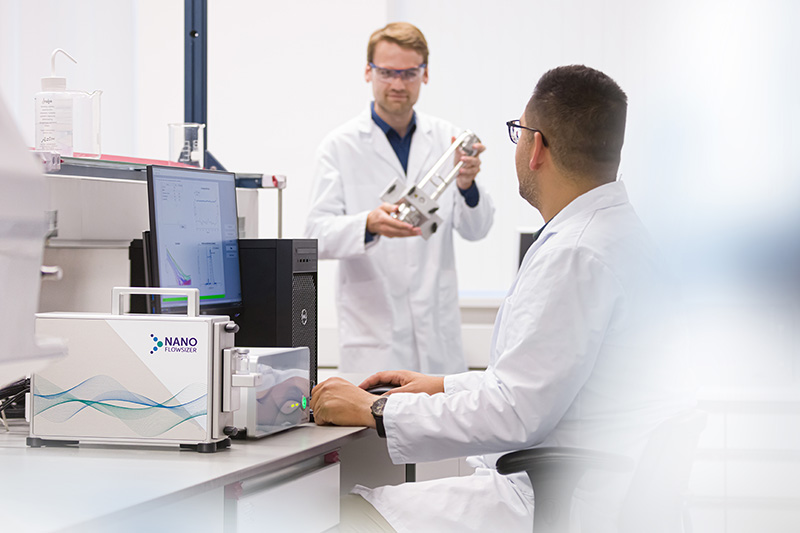

Our NanoFlowSizer solution concept includes the implementation of the instrument equipped with the right process connectors meeting your (process) requirements.

Approach:

- Initial Assessment

- Feasibility testing

- Application testing

- Implementation

- Long term service & support

1. Initial Assessment

- Screening of feasibility

- Customer objectives

- Product & Process information

- Test sample analysis at InProcess-LSP lab facilities

- Go/NoGo decision to move to next phase

2. Feasibility Testing

- Detailed objectives and Go/NoGo criteria

- Feasibility study

- Configuration requirements

- Feasibility statement: Go/NoGo for next phase

3. Application Testing

- Definition of optimal configuration

- Onsite installation and testing

- Possible fine-tuning

- Go/NoGo for next phase

4. Implementation

- Purchase & Installation instrument

- IQ/OQ testing

- User instruction

- Application support

5. Services & Support

- Long term support

- Application support

- Annual Performance check

1. Initial Assessment

The screening phase typically involves understanding of your objectives and a first feasibility assessment based on already available knowledge. Sample and process characteristics will be evaluated for expected NanoFlowSizer capabilities.

In case available sample information is not conclusive, one or more samples may be analyzed in our lab facilities. After a successful initial assessment more details of the application will be addressed during the Feasibility testing phase.

2. Feasibility testing

In this phase a detailed questionnaire about detailed sample and process information is available to list the most relevant parameters for further feasibility evaluation.

In case sharing detailed sample and /or process information requires a non-disclosure agreement, InProcess-LSP is of course very willing to sign.

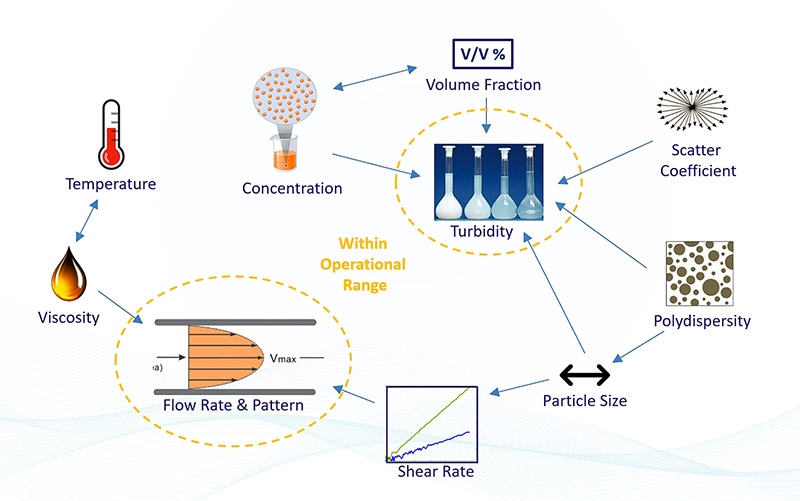

Important sample and process parameters that determine the final feasibility and performance of the NanoFlowSizer vary from type of sample, variation during processing, concentration, turbidity, applied flow rates, viscosity etc.

Since most of these parameters are linked to each other with respect to the expected performance of your application (see picture below), this phase may include further tests in our lab facilities to demonstrate that the NanoFlowSizer provides the solution to your challenge.

Static and under flow nanoparticle sizing

Experiments can be performed using your material under static and flow conditions.

3. Application Testing

After a successful feasibility phase, the optimal configuration and integration of the system into your process will be defined. The NanoFlowSizer system can be equipped with a wide variety of sample modules for different scales of processes.

The optimal location of the NanoFlowSizer system in the process will be defined as well. This may involve test cycles at the customer site to confirm adequate performance with respect to your objectives and requirements.

The application is then ready for implementation

Modular system with endless options

4. Implementation Phase

After the purchase of the equipment, the instrument will be installed according to IQ/OQ procedures which documents will be available for the customer.

After IQ/OQ, user instruction and application support will be included to make sure that your organization is ready to go.

Due to Covid-19 restrictions, installation including IQ/OQ testing are when necessary supported by remote installation support in combination with clear user instructions to setup the system.

We are proud to share that despite the travel restrictions we managed to install NanoFlowSizer systems and implement new applications successfully on a fully remote basis.

5. Support and Services

For long-term services and support from our specialists, two service and support packages are available: VIP and ELITE.

Besides ongoing application support and services, maintenance and annual performance checks (with certification) can be included as well as priority service. In addition, both the VIP and ELITE package offers various items such as accessories and training are included.

Rental options

In some specific situations a (temporarily) rental system is a preferred solution for an application. In this case a personalized solution can be further discussed.

Please, contact sales@inprocess-lsp.com to further discuss this option.

Supporting a fully customized solution for you = our focus

Questionnaire

Is the NanoFlowSizer suitable for our needs?

Receive direct feedback on your application.

Fill in your details, and receive the questionnaire immediately in your mail.

Submit this questionnaire with your application details to sales@inprocess-lsp.com.

You will receive our reaction within 2 days about the solutions we have for your application.