Emulsification using High Pressure Homogenization (HPH)

Emulsions in pharma and food industry

Emulsions are heterogeneous systems of two immiscible liquids, generally a lipid and an aqueous solution, where one of the phases is distributed in the other one as a continuous phase. Emulsions are used mainly in food and pharma industries. Different methods can be used to produce emulsions being high pressure homogenization (HPH) one of the most popular ones.

HPH is typically performed by forcing a liquid through a narrow nozzle at high pressure and by such establishing high shear stress. The droplet size can be adjusted by the levels of pressure and energy input.

By implementing the NanoFlowSizer in your inline process the droplet size can be monitored at real time and thus the process variables can be modified accordingly to obtain the desirable droplet size.

“Real-time process control in nanodispersion manufacturing via continuous nanoparticle size monitoring”

Real-time monitoring droplet size

Combining HPH with NanoFlowSizer

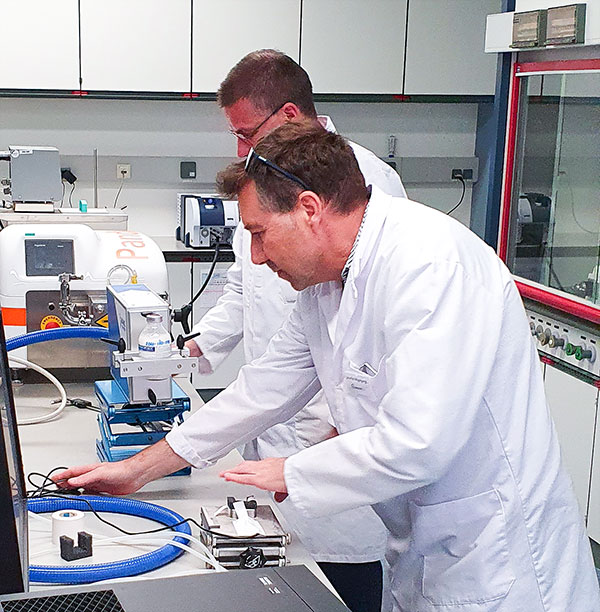

For feasibility studies we implement a Panda Plus 2000 HPH and different types of pumps to create the emulsification process on a small scale. For the monitoring of the particle size, the NanoFlowSizer is attached inline or in an online loop to the continuous process (Figure a).

InProcess-LSP will choose the appropriate flow cell from our catalogue depending on the flow rate and the characteristics of your process for the best performance.

“Real-Time Droplet Size Monitoring of Nano Emulsions During High Pressure Homogenization”

COVID-19 Patients in IC require nano-emulsion containing propofol

Anesthetics for Covid-19 patients

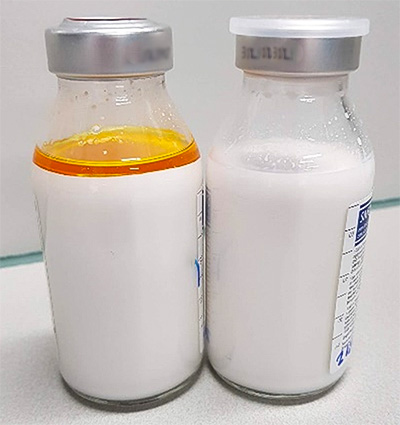

Corona patients on the ICs on life support should be kept asleep using medication. Due to the large number of ICU patients and the relatively long duration on life support, the availability of suitable sleeping aids, such as Propofol, is now a global problem. Very recently, the National Coordination Centre for Medicines (LCG) called on hospitals for a Propofol-saving policy.

Nano-emulsion Propofol

The NanoFlowSizer in combination with NIR spectroscopy was successfully applied to measure particle (droplet) size of a lipid nano-emulsion formulation with propofol.

To evaluate whether the propofol uptake in the lipid nano droplets …

Ref: Farmaceutisch Weekblad (Dutch)

InProcess-LSP is proud to contribute to lower the burden of the corona crisis, it’s motivating to see that our nanoparticle measurement technology plays an important role in this

Ad Gerich, CEO InProcess-LSP

Lipid Emulsions – Multi-PAT

InProcess-LSP also offers the possibility of combining different PAT technologies to have a wider information about your process. One of our most used MultiPAT configurations is a combination of an NIR probe with the NanoFlowSizer. The NIR probe will give the most relevant information about the chemical composition in solution at real time, whereas with the NanoFlowSizer will monitor the size of the nanoparticles present in suspension.

Combining NIR and NanoFlowSizer

The combination of these two PAT technologies offers extended possibilities for the production of lipid emulsions. Lipid emulsions have been clinically used, for decades, as an energy source for hospitalized patients by providing essential fatty acids and vitamins. Recent interest in utilizing lipid emulsions for delivering lipid soluble drug, intravenously, has been continuously growing due to the biocompatible nature of the lipid-based delivery systems.

Encapsulated API (active pharmaceutical ingredient)

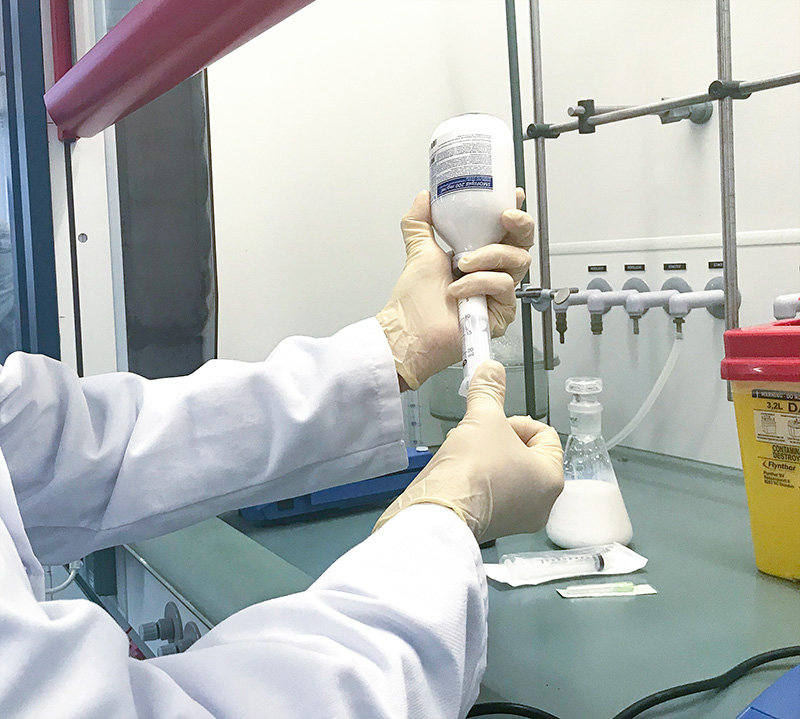

These formulations require an oil phase, an oil soluble API (active pharmaceutical ingredient) and an emulsifying agent (phospholipid) to disperse the oil phase into an aqueous phase. The manufacturing of emulsions will result in droplets that preserve lipids and a lipid soluble API encapsulated in egg phospholipids. Emulsions are unstable systems and undergo physical changes over time (e.g., aggregation, creaming, and increased droplet size), thus it is important to monitor the droplet size and the amount of drug dissolving during their manufacturing.

Non-invasive monitoring

The emulsification process is generally performed using a shaked flask (or other geometries) in which three phases are mixed. The flask is placed in the static set up of the NanoFlowSizer, and the NIR probe is placed outside the flask avoiding in this way any contamination (as shown in Figure 3).

Using this fully non-invasive monitoring, the dissolution of the API into lipid droplets and the droplet size can be evaluated on shaking without the need of dilution, giving flexible opportunities for formulation development.

Monitoring nanoparticles

Real-time and in-line for:

- Liposomes, vaccines, mRNA

- Emulsions

- Silica, iron, gold particles

- Protein molecules

- Polymers, inks, coatings

Innovate. Analyze. Win.

Case Studies & Articles

- How do results from different dynamic light scattering instruments compare?

- How can you improve your PEI-based transient transfection process?

- Monitoring Protein Aggregation During Downstream Processing – Insights Using the NanoFlowSizer

- Lipid-Based Nanoparticles: Manufacturing and inline size Characterization