Spatially Resolved Dynamic Light Scattering

the measurement principle inside the NanoFlowSizer

Think DLS, but with superior features

Discover Spatially Resolved Dynamic Light Scattering

Spatially Resolved Dynamic Light Scattering (SR-DLS) is the unique optical measurement principle developed by InProcess-LSP and integrated into the NanoFlowSizer. It delivers real-time nanoparticle size and size distribution directly in your process stream—even in turbid, concentrated, and flowing suspensions—without routine dilution or manual sampling.

It delivers real-time nanoparticle size and size distribution directly in your process, even under process-relevant conditions such as high turbidity, high concentration, and flow, without routine dilution or manual sampling.

Limitations of conventional DLS

If you rely on standard DLS instruments, you may recognize these challenges:

- You often have to dilute samples to get a reliable size result.

- Sampling means breaking sterility or opening a closed system.

- Measurements are usually offline in the lab, so feedback comes too late.

- High turbidity can make measurements unreliable or impossible.

- During continuous or fast processes, you only get intermittent snapshots, not a real-time picture.

The result: particle size – a critical quality attribute – is monitored only occasionally, instead of being continuously controlled.

SR-DLS was developed to remove these limitations and make nanoparticle sizing suitable as a true PAT tool in development and manufacturing environments.

Innovate. Analyze. Win.

What is SR-DLS?

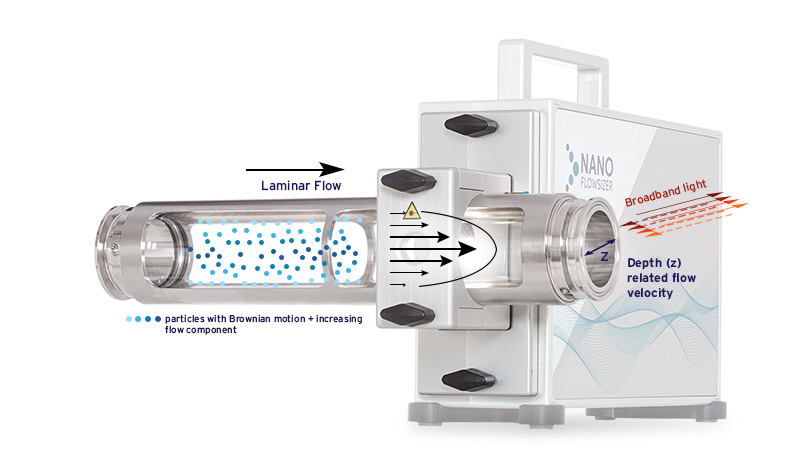

SR-DLS can be seen as DLS with depth (spatial) resolution.

Instead of collecting scattered light from a single, undefined measurement volume, SR-DLS combines low-coherence interferometry (LCI) with depth-resolved detection to interrogate multiple positions within the sample volume.

In SR-DLS:

- Low-coherence light is emitted into the sample (from a broadband source rather than a single-wavelength laser)

- Backscattered light is collected from multiple defined depths within the illuminated volume (spatial resolution).

- Correlation analysis extracts Brownian motion (particle diffusion), while dedicated algorithms quantify and correct for flow-induced motion.

Because the signal is linked to a defined depth (optical pathlength), SR-DLS can automatically select regions dominated by single scattering and suppress contributions from multiple scattering.

This enables robust size measurements in optically challenging samples, while flow correction preserves accuracy in moving streams.

Figure: The depth-resolved light scattering holds information on particle movement caused by both Brownian motion as well as flow rate. The contribution due to Brownian motion is used for the calculation of the particle size characteristics, while the flow rate information is obtained instantaneously for every measurement as well.

From principle to practice:

SR-DLS in the NanoFlowSizer

- One instrument for inline, online, at-line and off-line measurements

- Compatible with a wide range of transparent containers and flow geometries

- Measurement times typically within a few seconds, enabling continuous monitoring

How do results from different dynamic light scattering instruments compare?

Explanation of how results from DLS instruments at different wavelengths and scattering angles are related using practical examples, computer simulations and established light scattering theory.

In the context of the NanoFlowSizer SR-DLS technology using Near InfraRed light.

Technical Whitepaper:

Synergy. Innovation. Excellence.

Why SR-DLS works where other methods are limited

Handles high turbidity without dilution

Thanks to depth-resolved detection and automated selection of clean single-scattering signals, SR-DLS can measure:

- Highly concentrated and optically turbid samples

- Process streams where dilution is not desirable or not possible

- Real formulations and intermediates – not just “lab-prepared” diluted versions

Result: less sample preparation and fewer artefacts introduced by dilution.

Works directly in flow

Conventional DLS assumes a static sample. SR-DLS is designed for flow and can be deployed inline:

- Measures in tubing, flow cells or vessels in the process line.

- Separates flow-induced motion from Brownian motion and corrects for the flow contribution

- Delivers size data in seconds across a wide range of flow rates—from lab development to production-scale throughput

This enables continuous, inline monitoring instead of periodic manual sampling.

Non-invasive and sterile-friendly

With NanoFlowSizer, SR-DLS is non-invasive: optical components remain outside the process stream. This supports:

- Closed, sterile, or contained systems

- Maintain sterility

- Integration into existing equipment with minimal modification

Accurate particle sizing during manufacturing is widely recognized as a key challenge for bringing nanomedicines to market. SR-DLS helps close this gap by providing actionable, real-time size information directly where the process happens.

EMA/FDA: “one of the greatest challenges in bringing new nanomedicines to market is accurately determining their particle size during manufacturing”

Features & Benefits

What SR-DLS means for your workflow

By moving from conventional DLS to SR-DLS with NanoFlowSizer, you can:

- See particle size trends in real time

- Shorten feedback loops

- Reduce sampling and lab workload

- Increase process robustness

- Support QbD and PAT strategies

Where SR-DLS makes the biggest difference

SR-DLS is particularly valuable when you:

- Work with LNPs, liposomes, nanoemulsions or other turbid nano-formulations

- Develop continuous or semi-continuous processes (e.g. high-pressure homogenization, mixing, milling)

- Need to monitor particle size in sterile or closed systems

- Want to scale from R&D to manufacturing using the same measurement principle

- Aim to implement PAT-based control and reduce dependence on offline QC testing

Want to discuss feasibility for your process stream (turbidity, concentration, flow rates, integration points)?

Contact us at sales@inprocess-lsp.com

The right size, right on time.

Case Studies & Articles

- How do results from different dynamic light scattering instruments compare?

- How can you improve your PEI-based transient transfection process?

- Monitoring Protein Aggregation During Downstream Processing – Insights Using the NanoFlowSizer

- Lipid-Based Nanoparticles: Manufacturing and inline size Characterization