Real-time monitoring particle synthesis

Nucleation and growth of particles during their synthesis is monitored by the NanoFlowSizer with real time feedback. The NanoFlowSizer is capable of detecting changes in the backscattered intensity over time which are directly related to the concentration and size of nanoparticles in suspension.

This feature brings new opportunities to track the nucleation and/or growth of the particles at real time.

Differentiate between aggregation and particle growth

Extracting this critical information together with the inline particle size analysis during the synthesis of your compound will give you a deeper understanding of your process.

Being able to differentiate if the increase in the particle size is related to the growth of the particles (backscattering intensity increases), or to the aggregation of particles (backscattering intensity stays constant).

We have a wide experience monitoring the synthesis of many NanoParticles i.e. silica (stöber reaction), TiO

Synthesis setup

For our feasibility studies we have at our disposal a large variety of setups to monitor your process in the most efficient way. The synthesis can be monitored using a static or an inline setup:

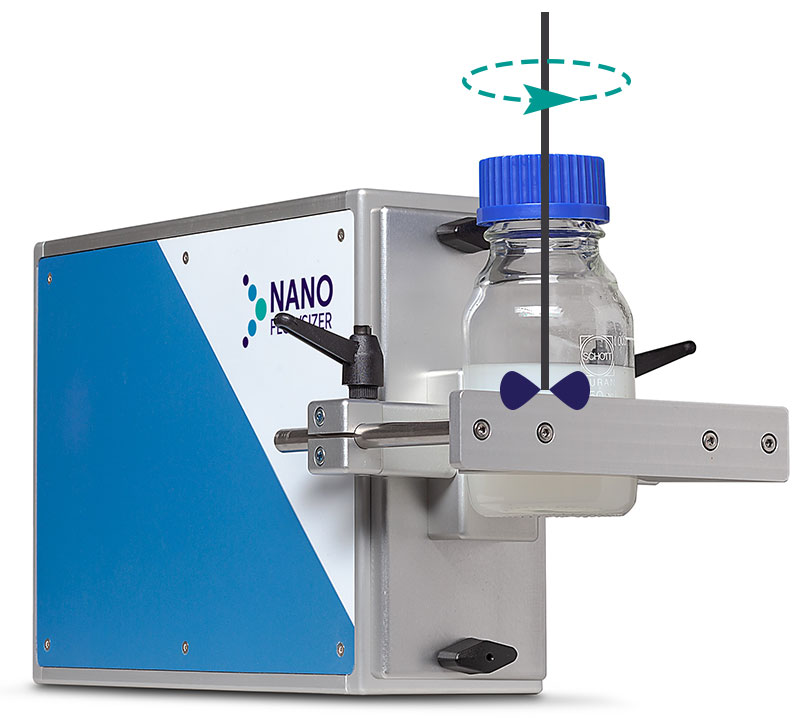

a) Static mode

Synthesis takes place in a stirred flask. The flask is placed in the NanoFlowSizer and the particle size and the backscattered intensity are recorded every certain time to monitor the growth of the particles. Figure 1a shows an image of the static mode setup.

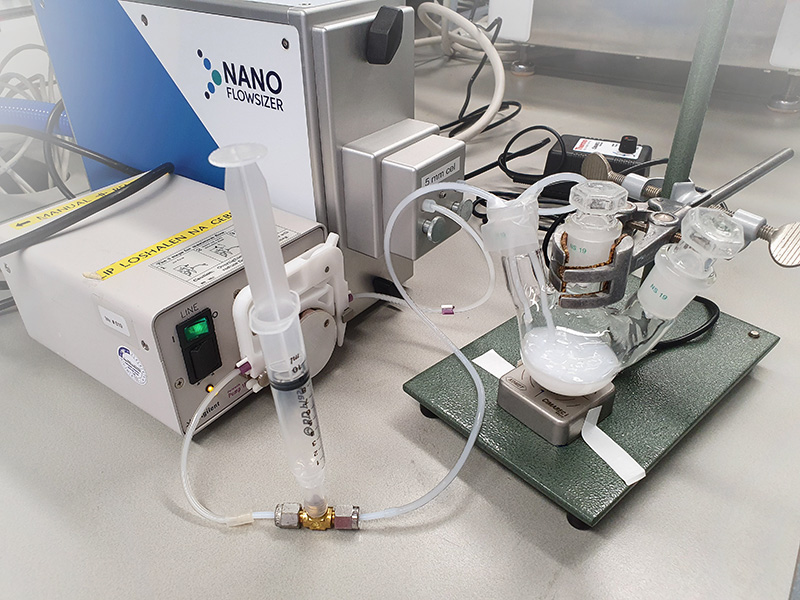

b) Inline mode

Synthesis takes place in a stirred flask. The suspension is circulated through a cell with the NanoFlowSizer connected to it. Figure 1b and c show images of the inline mode setup, using a Micro flowcell and a 2 inch cell, respectively.

Monitoring nanoparticles

Real-time and in-line for:

- Liposomes, vaccines, mRNA

- Emulsions

- Silica, iron, gold particles

- Protein molecules

- Polymers, inks, coatings

Fast and real-time process control